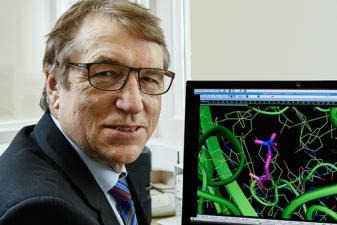

Andreas Manz

Microchip-sized analysis system

Winner of the European Inventor Award 2015 in the category Lifetime achievement

The super-small devices, collectively known as “Micro Total Analysis Systems" (µTAS), are only a few millimetres in size but include all of the mechanisms necessary for separating compounds into tiny amounts of liquid substances and detecting the compounds’ chemical makeup.

Micro-TAS (µTAS) units contain all of the micro-sized pumps and valves, as well as control and measurement electronics that are needed for in-field analysis. They also save on the time and space necessary for chemical analysis. By providing continuous remote monitoring these virtual laboratories on a chip are ideal for around-the-clock updates of environmental conditions or in-field disease and toxicology diagnosis.

Societal benefit

Lab-on-a-chip technology promises to revolutionize in-field monitoring and diagnosis. Future uses might include inexpensive, fast, point-of-care testing in more remote areas for endemic and pandemic diseases. For example, research is being carried out for µTAS diagnosis methods for HIV and malaria, as well as dengue fever, genetic diseases, localized toxins and several types of cancer.

For most of its potential applications, more costly lab tests already exist and the advantages lie in bringing adequate analysis areas that are impoverished or difficult to access.

Economic benefit

Currently, the central applications of lab on a chip technology are in medical and biotechnological fields, although implementation of the technology revolution is happening at a slower pace considering its potential. A 2011 market research report forecast that the biochips market, of which µTAS are a part, will reach € 7.8 billion (US$ 9.6 billion) by 2016, a jump from € 2.8 billion ($ 3.5 billion) in 2010. A more recent report from 2014 estimated that the market would grow by 18% between 2014 and 2019.

A modern embodiment of Manz’s μTAS system is the lab on a chip USB stick designed by 2014 European Inventor Award winner Christofer Toumazou. This device decodes a patient’s DNA within minutes and has already been licensed out to several companies. Other point-of-care medical technologies do exist, such as home pregnancy or drug tests, but other, more complicated devices that could diagnose common diseases are still in the earlier stages of development. Making such devices commercially viable remains a major hurdle, but one necessary to overcome before they can be made available where they are needed most: in impoverished, remote areas where healthcare clinics lack effective diagnostic tools.

How it works

When, for instance, a drop of blood is inserted at one end of the device, its constituent molecules are transported past a system of nanometre-sized chemical sensors by pneumatic, electromotive or capillary action.

Once the sensor registers the concentration of a chemical compound being tested, it converts the results into an electrical signal. One benefit of Andreas Manz’ device is that its sensor doesn’t need to be very sensitive, because before the substance is even transported to a sensor, it is pre-treated to eliminate most of the chemical compounds which might otherwise interfere.

The inventor

Over the course of his illustrious career, Manz has published more than 250 papers in scientific journals – including his seminal paper on the novel concept of “total chemical analysis systems” – which are cited more than 11,000 times. He is the recipient of numerous awards, including being ranked 48th among the most impactful 100 chemists of the past decade. Manz in the main innovator behind at least 39 patents, several of these are related to μTAS technology.

Did you know?

Media gallery

Contact

European Inventor Award and Young Inventors Prize queries:

european-inventor@epo.org Subscribe to the European Inventor Award newsletterMedia-related queries:

Contact our Press team#InventorAward #YoungInventors