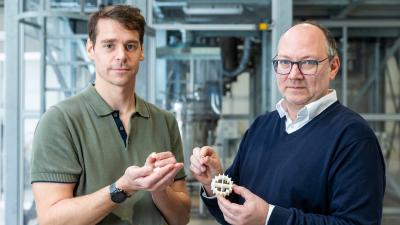

Josef Faderl, Siegfried Kolnberger, Thomas Kurz and Andreas Sommer

Corrosion-resistant steel for lighter and stronger car parts

Finalists for the European Inventor Award 2023

Driven by industrial demand, Faderl, Kolnberger, Kurz and Sommer began working on a zinc-based solution. Initially, several publications claimed that such a coating would be impossible to produce because of zinc’s melting and evaporation temperatures. The voestalpine team overcame this preconception. They focussed on how the addition of a very small amount of aluminium to the zinc melt could enable the coating to withstand the temperatures used in press-hardening by forming a very thin aluminium-oxide layer on the surface of the zinc coating.

The result of this development process was a steel and the corresponding hardening technology called phs-ultraform®. “The first meeting on phs-ultraform was on 17 April 2002,” recalls Faderl. “In 2005, we produced the first component with the coating and in the autumn of 2008, the first serial production started.” Today more than 30 million phs-ultraform-parts are produced yearly and assembled in more than five million cars per year.

Lighter steel, fewer emissions, safer cars

Press-hardened steel is fully recyclable and incredibly strong, enabling automakers to use less material when building cars, with reduced greenhouse gas emission during production. This also means lighter cars that use less fuel, potentially lowering emissions by 2 to 5 %. The steel in combination with the corresponding hardening technology is highly formable: car designers are able to shape complex components, combining high functionality with excellent crash protection.

Forming the perfect team

The team who developed phs-ultraform have decades of experience in the steel industry and forming technology, with each team member contributing a unique set of skills. Siegfried Kolnberger studied technical physics the Johannes Kepler University in Linz as did Josef Faderl, who later completed an executive MBA. Thomas Kurz studied material science, while Andreas Sommer, who graduated in mechanical engineering, has a background in sheet metal forming technology. Together, they continue to develop voestalpine's products and processes, helping to shape the future of the steel and metal forming industry.

Media gallery

Patent numbers:

Press materials

Access materials for journalists

Press release: Lighter and stronger steel for more sustainable transport: Austrian physicist selected as a finalist at the European Inventor Award 2023 Press photos/videos (for MXF format videos, please contact press@epo.org)

Contact

European Inventor Award and Young Inventors Prize queries:

european-inventor@epo.org Subscribe to the European Inventor Award newsletterMedia-related queries:

Contact our Press team#InventorAward #YoungInventors