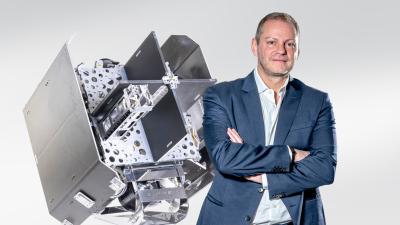

Kai Wu and team

Li-ion batteries that lower fire and explosion risks

Winners of the European Inventor Award 2023

As global pressure mounts to burn fewer fossil fuels, the automotive industry has been in a race to develop electric vehicles (EV). Powered by batteries, electric cars are becoming increasingly popular - in 2018, advances in Li-ion cells were responsible for 45% of patenting activity related to battery cells. Although EVs are less likely to ignite than combustion engines, fires ignited in Li-ion batteries burn hotter and faster, require more water to be extinguished and can reignite hours or days later. Together with his team at CATL, Wu has driven battery developments for over a decade. His journey began when BMW, one of the company's customers, asked the CATL team to minimise the risk of battery fires caused by overcharging.

The solutions developed by Wu and his team include a safety device that short-circuits an overcharged battery. The device features an embossed flip-top cover which does not melt – a unique feature in such devices. The cover acts as a barrier that dissipates heat and absorbs the temperatures and excess pressure. When overheating inside a battery cell causes the air pressure to rise, the cover flips and makes contact with the conductive pole piece in the battery, thereby stopping the charging process.

Li-ion battery cathodes are traditionally made of lithium, nickel, cobalt and manganese (NCM) and are prone to overheating. Wu and his co-inventors experimented with Li-ion phosphate as it has a low energy density and operates at a low voltage range. When overcharged, Li-ion phosphate will not overheat, making it a safer choice for batteries. In traditional EV batteries, individual modules are connected to one another to form a battery pack. Since 2019, Wu and his team have been working on cell-to-pack (CTP) technology, which uses a single integrated structure for the pack. This structure optimises the space used in the battery pack and increases the pack's energy density.

Inspiring future inventors

Wu is the chief scientist and co-president of CATL and the co-president of the CATL Future Energy Research Institute. He began his career as a lecturer before moving into industry to work on magnetic recording. In 2002, he accepted a post as a technical director of a company that manufactures lithium batteries. Wu joined CATL in 2012 and has been a key figure in the company’s success.

His experience in academia and industry enables Wu to offer unique insight to aspiring inventors: “Ask more, learn more and do more. First, you cannot do everything, and you cannot know everything. So, you need to ask more [questions] and you can get to the point faster if there’s more effort put into the question. Secondly, you need to learn more. You cannot simply know everything by asking a question. You need to learn more, gain knowledge and experience so you understand what your next step will be. Lastly, do more. Practice what you’ve learnt, use theoretical learning to solve the actual problems.”

Media gallery

Patent numbers:

EP3104431B1, EP3121867B1 and EP3246967B1

Press materials

Access materials for journalists

Press release: Chinese scientist wins the European Inventor Award 2023 with a safer lithium-ion batteryPress release: Safer batteries reducing the risks of fire and explosions in electric vehicles: Chinese scientist selected as a finalist at the European Inventor Award 2023 Press photos/videos (for MXF format videos, please contact press@epo.org)

Contact

European Inventor Award and Young Inventors Prize queries:

european-inventor@epo.org Subscribe to the European Inventor Award newsletterMedia-related queries:

Contact our Press team#InventorAward #YoungInventors