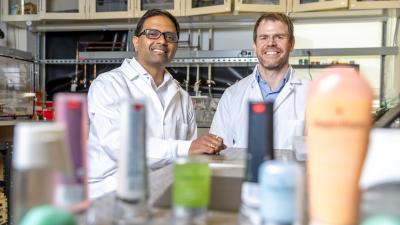

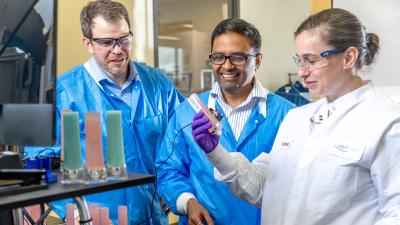

Kripa Varanasi, David Smith and team

Customisable non-stick packaging solution to reduce waste

Finalists for the European Inventor Award 2023

Trying to shake the final drop of ketchup from the bottle is a mildly frustrating experience for consumers, and possibly amusing for anyone watching. But when you add up the wasted product and the impact on recycling, it is no longer a laughing matter. According to estimates, some 15% of viscous products such as ketchup and cream cheese are wasted as their containers cannot be fully emptied. This equates to one million tonnes of condiments being thrown away every year.

Varanasi, Smith and their MIT group had been researching methods to reduce friction in pipelines to cut the energy cost of pumping fluids. They knew how to create slippery surfaces but were unsure of commercial applications. “We both had an entrepreneurial mindset from the beginning,” explains Varanasi. “Around this time, my wife was trying to get honey out of a bottle, and she prompted me to solve this problem. So that got us thinking about packaging.”

An idea that stuck

In containers, there is always friction at the interface between the solid container wall and the liquid inside, which is why the product sticks to the container. The MIT team modified that interface with a composite solid liquid surface that eliminates friction.

Varanasi and Smith entered the MIT-100K business plan competition and won the Audience Choice award, causing “a perfect storm of great things that came together,” as Varanasi describes. “There was a big pull from the market, a technology that was great and couldn’t be easily duplicated or replaced, we had intellectual property protection for all these things, and an investment community which was excited.”

They founded LiquiGlide in 2012 to commercialise their coating. Today, the company offers customised chemical coatings that cling to textured packaging while repelling the products inside them, allowing substances as sticky as paint, ketchup and toothpaste to slide out effortlessly, leaving no traces behind. Their team is exploring potential uses for the invention, including in medical devices like catheters, large containers or tanks, and preventing ice build-up.

Bonded by a love of engineering

Varanasi studied mechanical engineering at the Indian Institute of Technology (IIT) and at the Massachusetts Institute of Technology (MIT). Smith studied mechanical engineering at the Polytechnic University of Turin in Italy and the University of Illinois Urbana-Champaign in the US before completing his master’s at MIT.

Smith was one of Varanasi’s first graduate student at MIT and seemed destined to pursue a career in engineering: “I always enjoyed math and physics more than any other subjects…I was always fascinated by new inventions and new technology. I thought that was really cool and wanted to be a part of that, wanted to build things, wanted to invent things. Everything else didn't sound nearly as interesting to me.”

Media gallery

Patent numbers:

EP2969257 B1

Press materials

Access materials for journalists

Press release: Maximising product and minimising waste with innovative packaging: Inventors from MIT selected as finalists for the European Inventor Award 2023 Press photos/videos (for MXF format videos, please contact press@epo.org)

Contact

European Inventor Award and Young Inventors Prize queries:

european-inventor@epo.org Subscribe to the European Inventor Award newsletterMedia-related queries:

Contact our Press team#InventorAward #YoungInventors