Building a greener future

Last updated: 3.11.2022

At present, around 35% of buildings in the European Union are over 50 years old and almost 75% of building stock is energy inefficient. Overall, only about 1% of building stock is renovated each year. Although the European Green Deal will help ramp up building renovation strategy, sustainable innovation in areas such as building materials is urgently needed. The same applies to infrastructure more generally.

First among the heavy industries in terms of global CO2 emissions is iron and steel production, which accounted for 2.6 gigatons of CO2 emissions in 2019, which is more than the total for all the world's road freight. In recent years, the biggest source of emissions within the transportation sector has been passenger cars, with medium and heavy trucks not far behind.

If our entire infrastructure is well overdue for a major overhaul in terms of sustainability, then so are the farming and fishing sectors, particularly in the face of challenges relating to both population growth and climate change. This is where smart agriculture comes into play. Finally, the production, use and disposal of materials such as plastics is another major area of concern. However, here too innovation is shaking up the way things are done for the sake of sustainability, in this case both in terms of plastic recycling and bioplastic technologies.

United Nations Sustainable Development Goals

Innovation in the field of technologies for building a greener future supports a variety of United Nations Sustainable Development Goals, mainly:

- Towards a more sustainable cement industry

About 71% of the Earth's surface is covered by water, a huge potential source of renewable energy that can be harvested using various technologies - some of which are very old, some very new.

Hydropower (or hydroelectric power) is generated by converting the energy of flowing or falling water into electricity. The waterflow can be used to rotate a turbine, which in turn actuates an electrical generator that produces power. There are many different water turbine technologies. Large-scale projects use dams to generate electricity. Among the largest in the world is the Three Gorges Dam in central China, with 32 main turbines spanning the Yangtze River, each with a capacity of some 700 megawatts. Smaller scale units on rivers or waterfalls elsewhere may generate just a few kilowatt-hours.

Some hydroelectric power plants generate electricity during peak hours and then pump the water back at periods of low demand to repeat the cycle. This provides a valuable opportunity for such plants to "store" electricity from other more intermittent renewable energy sources. Excess wind power can, for example, be used to pump water upstream that can then be used as required.

Hydropower is the leading renewable energy technology by capacity and generation. In 2020, hydropower accounted for 17% of global energy generation, making it the third most significant energy source overall, after coal and natural gas. Its contribution is 55% greater than nuclear's and outstrips that of all the other renewable energy sources combined, including wind, solar photovoltaic, bioenergy and geothermal.

However, hydropower is usually restricted to freshwater areas. So what about all the salt water out there? Ocean energy technologies are the answer. They can be used to generate electricity from the tides (tidal range systems), subsea currents (tidal stream systems), natural temperature differences in oceans (ocean thermal energy conversion, or OTEC) and waves (wave energy convertors or WECs). However, most of these technologies are still at a relatively early stage of development. By the end of 2018, for example, only 243.4 megawatts capacity of ocean energy had been officially registered in EU member states.

Discover inventors' stories

Ido Sella and Shimrit Perkol-Finkel

Learn about a new type of concrete developed by the Israeli entrepreneurs Ido Sella and Shimrit Perkol-Finkel (1975-2021) to make marine infrastructure more habitable for native marine life.

Hendrik Jonkers

Discover how a self-healing bioconcrete invented by the microbiologist Hendrik Jonkers aims to provide a cheap and sustainable solution for markedly improving the lifespan of buildings, bridges and roads.

Search patent information

Climate change mitigation technologies relating to the industry can be found in the Y02 classification scheme:

- Green lighting

In the European Union, homes, business premises and public buildings account for about 40% of all energy consumption and 36% of energy-related greenhouse gas emissions. Together, these buildings comprise the single largest energy consumer in Europe. Moreover, heating, cooling and domestic hot water accounts for 80% of citizens' energy consumption. However, there are a host of innovative, green building technologies that can be used to give Europe's buildings an energy-efficiency makeover. This quickly becomes apparent from focusing on just a couple of relatively specialised subareas of relevance to almost all buildings.

Smart glass

Smart glass can reduce energy consumption in buildings by around 30%, simply by altering the tint of the glass as conditions change. This enables the levels of natural light, as well as of ultraviolet radiation and infrared, to be regulated, along with the temperature of the building's interior. In this way smart glass can contribute significantly to more energy-efficient buildings.

LED lighting

European regulations restricting hazardous substances like mercury in electrical and electronic equipment are also helping to drive innovation in such areas as lighting. A new generation of highly efficient solar powered LED lighting systems can help support community life after dark and enable businesses to extend trading hours almost anywhere on Earth.

These systems promote effective and affordable ways to lower energy consumption. LEDs require about one tenth of the energy of incandescent light bulbs and roughly half of that of compact fluorescent lights (CFLs). They also last at least 40 times longer.

Another advantage of LED lights is that they enable better facial recognition and adequate colour perception, not only by the human eye, but also by security cameras, which reinforces crime prevention efforts and improves safety in public spaces. The relatively recent use of LEDs in city lighting has enabled lights to be dimmed in specific places at specific times as required, resulting in energy and maintenance savings of up to 70% compared to conventional lighting.

Discover inventors' stories

Advances in smart glass and LED technologies have also featured in the European Inventor Award.

Jean-Christophe Giron

Unlike previous incarnations of tintable glass that change colour automatically when certain thresholds of heat or light are reached, Jean-Christophe Giron’s product can be controlled according to personal preferences, heralding a new era of architectural lighting.

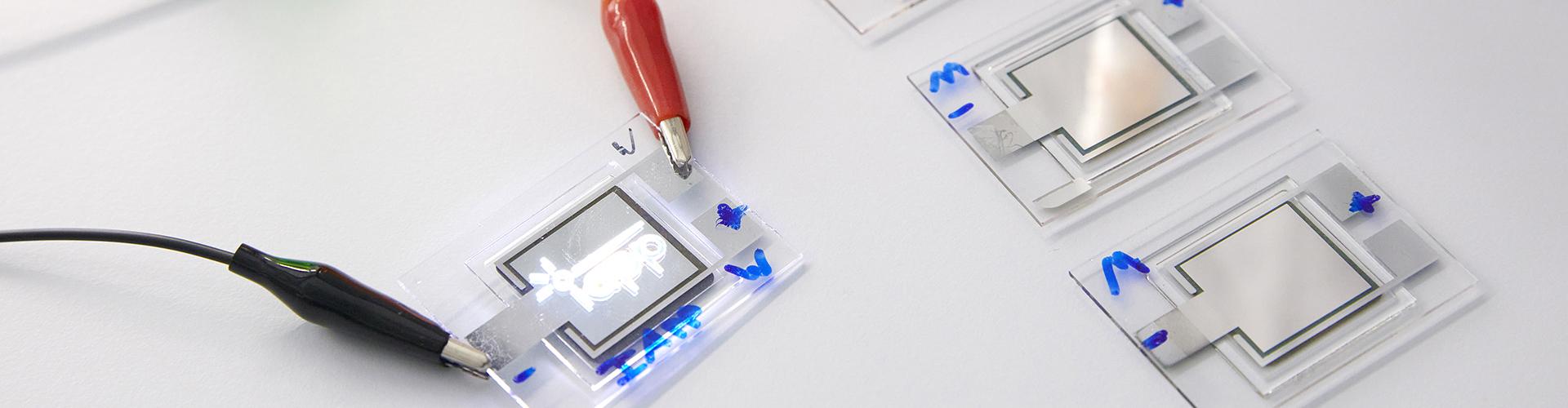

Karl Leo

His pioneering work with semiconductors led to the development of the light emitting diode (LED) and organic light emitting diode (OLED), which transformed the electronics industry. Upon receiving his European Inventor Award for lifetime achievement, Karl Leo said: "I see opportunities much beyond what has been achieved today: flexible, lightweight, environmentally-friendly organic electronics can be applied almost everywhere."

Search patent information

Further green lighting inventions can be found in the Y02 classification scheme for climate change mitigation technologies:

- Green iron and steel

-

Image

The world's iron and steel industries accounted for roughly 8% of global CO2 emissions in 2020. The refinement of iron ore traditionally requires the natural resource to be mixed with a carbon-containing reductant in an enormous blast furnace. This leads to the emission of roughly two tons of CO2 for every ton of iron produced. Much of the iron is then further refined to produce the various kinds of steel found everywhere from appliances, cars, trains, ships and aerospace to heavy equipment, buildings and infrastructure.

Fortunately, the steel industry and research institutions are working hard to find better, cleaner and more sustainable ways of working. One aspect of the green transformation of the steel industry emerged decades ago, namely the development of alternative ways to heat blast furnaces, so as to move away from the use of hydrocarbons. Electric arc furnaces, for example, can be heated at least in part using renewable energy such as wind, solar or hydropower.

A promising steel production process that avoids the use of fossil fuel and draws on existing industrial processes is hydrogen direct reduction. Instead of carbon-containing reductants, hydrogen is used. The gas can be produced through electrolysis powered by renewable energy and, instead of producing large amounts of CO2 when used as a reductant, primarily emits only water vapour.

Finally, iron and steel producers are looking to make better use of the thermal energy produced in existing processes. Combined with CO2 recuperation and sequestration where appropriate, the gains can be considerable. The recycling of old iron and steel is also increasing, especially as the amount of energy required for recycling processes decreases. However, fresh new iron is still required to meet the needs of infrastructure, construction and automotive sectors, among others.

Search patent information

Climate change mitigation technologies relating more generally to metal processing can be found in the Y02 classification scheme:

- Green transportation

There are many ways to make mobility greener, drawing on research in a host of fields from electric vehicle batteries to the race for green aviation (e.g. cleaner fuels, improved aircraft design). Innovation is continuously reducing the amount of waste generated in the production of vehicles, across the board. Meanwhile, developments in image processing and detection systems are supporting gains in efficiency when it comes to the operation of both vehicles and infrastructures. The focus of this section is on road transportation.

Self-driving vehicles: Making road transport more efficient

Truck platooning has great potential when it comes to safer, cleaner and more efficient road transport. With one of several trucks programmed as platoon leader, and the rest programmed to follow directly behind at a set distance, aerodynamic drag decreases and energy consumption is reduced.

This is enabled by vehicle-to-vehicle (V2V) communication and associated protocols, which ensure the reliable and safe transfer of data. Advanced driver assistance systems (ADAS) incorporate steering and braking functions, including advanced emergency braking systems (AEBS). Finally, driver monitoring and human-machine interfaces ensure driver awareness.

Making electric vehicle charging infrastructure more accessible

Electric vehicles are considered crucial to making transportation more sustainable, including by enabling greater use of renewable energy sources to power mobility. Yet charging electric vehicles remains a challenge. Contactless charging solutions are appealing and require no manual handling of charging equipment. However, they have traditionally been plagued by low efficiency, coupled with difficulties with aligning energy transmitters and receivers. Energy transfer using magnetic resonance is a potential game changer here, especially now it is technically viable at application level. The method makes charging highly efficient, reducing the potential impact of misalignment and distance. Various solutions have been developed which even allow for energy transfer while driving.

Breakthroughs in battery management

While the principles of hybrid and electric vehicles have been known for decades, large-scale commercial success has been hampered by issues such as reliability and cost. Major advances in battery technology are beginning to change this. As is typical for the automotive industry, it is often with the accumulation of many small steps and changes that significantly increased ranges and more durable components are achieved as production costs are cut. For example, connecting a low-voltage battery via a propulsion motor and its electronic controls to a high-voltage main traction battery has proven to greatly improve power management efficiency.

Improvements in the production of automobiles

The recycling of materials and reduction of waste in automobile production can make a major contribution to sustainability. The "vegan" vehicle interior, for example, eschews leather in favour of fabrics made from recycled PET bottles, plastic waste retrieved from the oceans or vegetable and plant by-products.

Learn more

For more background on the role of patenting in autonomous driving, see the EPO's 2018 study entitled Patents and self-driving vehicles.

Discover inventors' stories

Several inventions nominated for the European Inventor Award have contributed to a smarter and more sustainable transportation sector.

Frank Herre and Hans-Georg Fritz

Together with their team, the engineers Frank Herre and Hans-Georg Fritz developed an automated car-painting system that applies paint without wasting a single drop, cutting waste and saving energy.

Carmen Hijosa

One of the versatile materials that you can now expect to find in a car’s vegan interior was invented by Spanish entrepreneur Carmen Hijosa. Her pioneering textile is made of pineapple leaves and can be produced with less environmental impact than cow leather.

Amnon Shashua

Israeli computer vision expert Amnon Shashua and his team have developed an advanced driver assistance system that uses a single-lens camera and cutting-edge artificial intelligence to spot and avoid traffic hazards in real time.

Stéphane Kemkemian, Pascal Cornic and Jean-Paul Artis

This trio of French scientists benefited from being at the centre of a classic innovation ecosystem with close relations to academic partners and small and medium enterprises. Their contribution to making driving safer and more sustainable: advance cruise control.

Shoichi Sasaki

Until the mid-1990s, lack of battery performance stalled the commercial use of hybrid cars. Things changed with Shoichi Sasaki’s development of a new breed of power-management system.

Search patent information

Climate change mitigation technologies relating to this sector can be found in the Y02 classification scheme:

- Smart agriculture

Just as ways of doing agricultural evolve continuously, agriculture per se continues to provide an absolutely essential foundation for all our societies. This applies not only to nourishment, but also to the provision of many key raw materials. Food security and the end of hunger is also one of society's fundamental aspirations, as reflected in the UN Sustainable Development Goals.

However, between now and 2050, the global population is forecast to grow from almost 7.7 billion to 9.8 billion. This is expected to require a 60% increase in global food production, a tremendous challenge, especially when coupled with the general loss of soil fertility and available land for farming. Climate change, rapid urbanisation and the growth of various industries further complicate these issues.

Innovation in agriculture will be key to addressing these challenges in a green and sustainable way. Revolutions in agriculture have profoundly transformed societies and civilisations ever since farming began. Today, we have the privilege of witnessing the next revolution: the use of modern information and communication technologies to increase agricultural yields in a green and sustainable way.

Smart agriculture uses artificial intelligence, autonomous or robotic vehicles, satellites, next-generation sensors and computer implemented methods to assist decision-making. It also reduces the ecological footprint of farming. Minimized or site-specific application of inputs, such as fertilizers and pesticides, mitigate both leaching problems and greenhouse gas emissions. Sensor networks allow near continuous monitoring of farms. Real-time data on soils, plants and animals help steer production inputs such as water, fertiliser and medication. Farmers in both developed and developing countries stand to benefit.

Smart agriculture is green agriculture. We at the EPO are proud to support innovation, including in this sector, which greatly contributes to a safer, smarter and more sustainable world.

Discover inventors' stories

European Inventor Award finalists have made diverse contributions to reducing the impact of agricultural practices on the environment and improving animal welfare.

Carmen Hijosa

Over 27 million tonnes of residual biomass from the pineapple harvest are discarded every year. Imagine: according to Carmen Hijosa, this alone could replace all the leather currently produced globally each year for shoes, without using additional land and resources.

Alexander van der Lely and Karel van den Berg

An automated system designed by this inventive Dutch duo allows cows to decide when it’s time to be milked. The system keeps animals happy and healthy, and equips farmers with diagnostic tools to operate more efficiently.

Esben Beck

Sea lice severely impact salmon farm populations across the globe. To put an end to this parasitic problem, the self-taught inventor Esben Beck developed an underwater robot that uses image recognition, artificial intelligence and lasers to repel the threat and help cultivate healthier salmon.

António Velez Marques, Helena Pereira, Rui Reis, Susana Silva

These Portuguese inventors masterminded a way of giving cork extra volume using only microwaves and water. Their invention supports a centuries-old, traditional industry that employs tens of thousands of workers in Portugal and other cork-producing countries. Moreover, it does so without sophisticated machinery or harmful chemicals.

Search patent information

Climate change mitigation technologies relating to this sector can be found in the Y02 classification scheme:

Y02A40/00: Adaptation technologies in agriculture, forestry, livestock or agroalimentary production.

Y02P60/00: Technologies relating to agriculture, livestock or agroalimentary industries

- Innovation for tomorrow’s plastics and plastic recycling

The impact of today's linear plastic economy on the triple planetary crisis of climate change, biodiversity loss and pollution point to a catastrophe in the making. This is an issue that can only be solved through international co-operation, innovative business models and new technologies.

In March 2022, UN member states committed to end plastic pollution and forge a legally binding international agreement by 2024. This would accelerate the transition to a circular plastics industry that focusses on the design of reusable, recyclable and biodegradable plastics, considers plastic waste as a resource for new materials, and reduces the overall need for plastic usage.

The good news is that innovation can make a difference. By improving waste management and plastic recycling, new technologies can accelerate the achievement of a fully circular model that keeps materials flowing in a "closed loop" system, rather than being used once and then discarded.

Plastics for extended use and easier recycling

In 2019, the global production of plastics reached 368 million metric tons - equivalent to the weight of roughly two-thirds of the entire human population. Bearing in mind forecasts that plastic production will more than double by 2050 -exceeding our ability to collect the waste - innovators are increasingly researching plastics that are easy to repair or even self-repairing. Plastic materials are becoming increasingly reusable as a result.

Fossil-free plastics

To reduce the negative environmental and societal impact of plastics, various plant-based and biotechnological options are being explored. In a related area of innovation, CO2 or even methane generated from industrial processes is being used as a raw material for manufacturing plastics. These developments are resulting in all manner of eco-friendly packaging and various other versatile products.

Recycling

The key to most advanced recycling technologies in this field is sorting and separating plastics. Approaches that overcome the issue of polymer degradation in conventional mechanical recycling include solvent-based techniques to separate polymers from additives. Chemical and enzymatic depolymerisation routes selectively break down polymers into monomers, providing the possibility of building plastics that are circular by design.

Learn more

Drawing on the EPO's latest patent data, our Patents for tomorrow's plastics study offers key insights into potentially game-changing chemical and biological recycling methods for producing virgin-like plastics from waste. The study shows that, in the race for a circular economy for plastics and alternative plastics technologies, universities and public research institutions are developing 29% of advanced recycling technologies in Europe. Commercialising these technologies nevertheless remains a challenge. Learn more about Patents for tomorrow's plastics and listen to a podcast featuring two of the report's co-authors.

Discover inventors' stories

Alternative plastics and recycling technologies have regularly featured in the European Inventor Award in recent years.

Victor Dewulf and Peter Hedley

The joint-winners of the EPO's first ever Young Inventor Prize invented an AI-driven waste recognition and sorting system that can even distinguish between food-grade and non-food-grade plastics.

Christoph Gürtler and Walter Leitner

Not only does their invention reduce energy usage. It also recycles waste CO₂. A productive collaboration between industrial research and academic science enabled these German chemists to discover how to use CO₂ to make greener plastics.

Klaus Feichtinger and Manfred Hackl

Thanks to the work of Klaus Feichtinger and Manfred Hackl, a wider variety of plastic waste can now be turned into pellets, ready for industrial reuse and indistinguishable from new plastics. Learn more about their higher-performance plastic recycling.

Eben Bayer and Gavin McIntyre

Find out how these US entrepreneurs and committed environmentalists discovered a source of eco-friendly packaging in mushrooms. The result: a new class of degradable biomaterial that can be moulded into almost any shape.

Thomas Scheibel

Over 300 million years of evolution have produced one of the world's strongest materials – the silk fibres of a spider web. Now, thanks to this German biochemist, it is possible to mass-produce spider silk as a next-generation industrial fibre.

Gert-Jan Gruter

Imagine: plant-based plastic bottles that are robust, malleable and recyclable but require about 70% less energy to make than conventional PET bottles. Learn how the invention of a savvy Dutch chemist could shake up this industry.

Ludwik Leibler

Self-healing plastics that can repair themselves may once have sounded like science fiction. Now they’re a reality, thanks to inventions like that of this Polish-born French physicist. Find out about vitrimers, a new class of polymers.